I'll start with the moving parts.

Every function in a typewriter takes a number of moving parts. Often, one single function (for example, typing the letter 'k') involves many moving parts. Now when I say 'moving', I'm talking about a number of simple machines. Remember grade school physics? Planes, levers, wedges, and wheel & axels. Typewriters are chock-full of these. Every single time you press a button, you activate many of them. Staying with the example of pressing the letter 'k', on a Royal KMM, you invoke over 15 simple machines... and maybe more if you count some of the secondary and indirect functions.

Generally, if I'm refurbing a machine, it's because the wear isn't great enough to make me start replacing parts. If the machine is that worn, I pass on it.

What I do have to deal with is: RUST, DIRT, GRIME, and OLD GREASE (the oil that is used on these tends to gunk up over the years and it ends up causing things to stick instead of slide.)

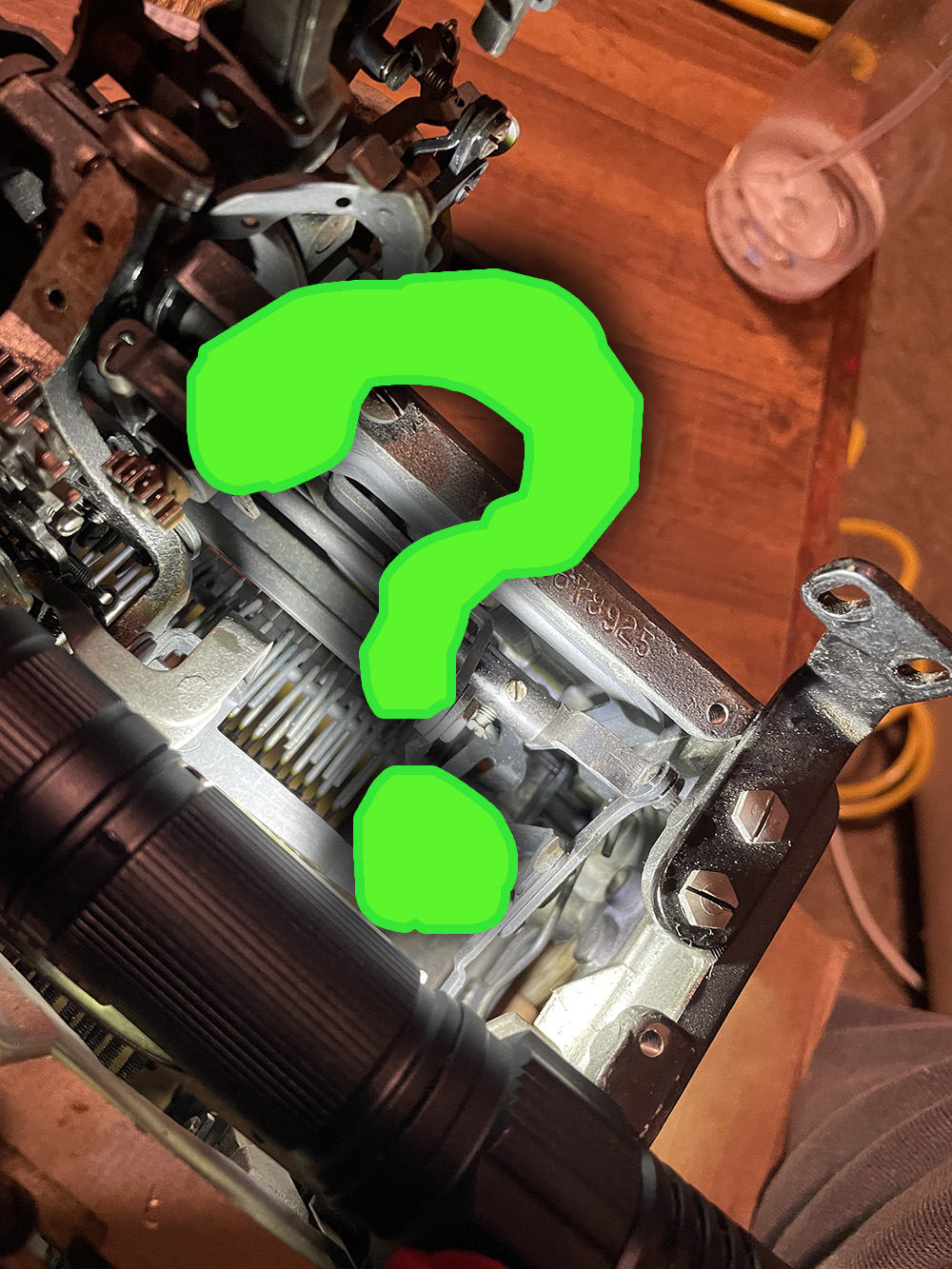

In the pictures below, I'm dealing with the TAB SET function. I start by identifying ALL of the moving parts. I've tried to highlight and zoom in on them, but it's not the easiest thing to see in a picture. Even a video would be confusing.

I start with the rust. Every moving part gets a drop or two of either PB Blaster or WD40. Then I work the movement back and forth--usually about 50 times. I want the oil to work it's way into the shaft or hinge or whatever metal parts are rubbing against each other. Back and forth I wiggle it, back and forth, back and forth.

It's rare that there's really any rust there, but this movement also break up dirt and old grease. But now that the dirt, grease, and rust is loosened, it's time to clean it. I hit it with a spray bottle full of denatured alcohol. Maybe one or two sprays, then I wiggle it back and forth another 20 times. Then I spray them all again. Back and forth 20 times.

Finally, if all the alcohol dripping from the parts looks clean, I blow it with a blast from the air compressor (canned air works). Enough to get rid of the alcohol and mostly dry it.

Before lubricating anything, I go through the entire machine this way. It's no use oiling something if you're still spraying alcohol everywhere. But once I'm satisfied, I go back to those parts.

Now I've heard some technicians claim that you should never oil these parts. They claim that the oil only gunks up and causes problems later.

That's foolish.

BUT--it won't wear.

Metal parts wear when they rub. I've been a technician my entire adult life (and most of my teenage life). I've worked on everything from furnaces to printers to manufacturing equipment. Metal parts wear into each other and the only way to minimize it is to oil it.

In fifteen years, you'll have to go back and clean up that oil--but what you won't have to do is replace parts that have cut grooves into each other. That's Mechanics 101.

My favorite oil is this Tri-Flow:

https://www.amazon.com/dp/B07QWB6PKV?psc=1&ref=ppx_yo2ov_dt_b_product_details

Aside from it working well, I think the odor is pleasant (compared to WD40). If I'm out, I'll use gun oil.

Each moving part gets a single drop. And then, yes, I wiggle it back and forth to work the oil into the grooves and notches.

And that's how I go through my machines, part by part, until I'm satisfied that every moving part is functional.

Of course, that's just the cleaning part of the process.

Next, I have to go through each function to make sure all the adjustments are properly set--which is enough for another post another time.